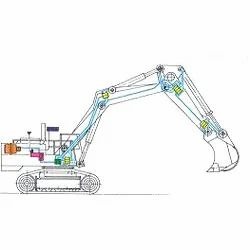

Vehicle Lubrication

Vehicle Lubrication Tubing

As the Vehicle Lubrication Tubings is operated at a main pressure of 100-150Kg/ cm and the line joining secondary block to the lubrication points, normally operates at 40-50Kg/cm2, corresponding tubing and fittings are recommended to be used Generally the fittings are of the following nature:

Advantage of this System

Ensures each point greased: The system ensures that grease reaches each point connected to the system unlike in manual point to point greasing where the person doing greasing may forget or may forget or miss some points. In centralized system, this is just not possible as all lubrication points are connected to one central source.

Proper amount of grease: The system ensures that proper amount of grease as recommended reaches each point.

Greasing while vehicle running: Greasing can be done while the vehicle is in the running condition. It need not be brought foe this purpose to the garage.

Minimize grease wastage: In manual point to point greasing, the general method is to keep pumping the grease till it starts flowing out. This wastes grease as well as needs subsequent cleaning of the points. If points are not cleaned, dirt and dust accumulates on those points and further greasing become difficult. In centralized system required amount of grease is ejected to lubrication point; hence there is no wastage of grease.

No prior cleaning/washing needed: Normally vehicles need washing before greasing particularly in manual point to point system, whereas in case of centralized lubrication this additional washing only for this purpose is not required.

Greasing under pressure: In manual point to point system grease dose not reach to the real point under pressure ant sometime it gives false indication of filling for completion of greasing. While in centralized system grease is done normally at a high pressure which ensures that grease has actually gone to the moving surfaces.

Fuel efficiency: Since greasing is done periodically as per requirement, the machine runs smoothly. The losses which normally occur because of friction between the ungreased parts is well reduced. This results in fuel efficiency of the vehicle.

Life of vehicle: In case of centralized automatic lubrication system, vehicle run smoothly as efficient of friction between sliding and rubbing parts significantly low; wear and tear of vehicle parts is very less as well as load on engine is less as compared to manually lubricated vehicle. This increase life of vehicle.

- From the pump to the master block 10mm OD seamless pipe is used with compression type of fitting.

- From the master block to secondary block 6mm OD seamless pipe is used.

- From the secondary block to the lubrication points again 4mm OD seamless pipe is used with compression fittings.

- Many times where the points are moving on the chassis/ necessary hoses are used.

- Particularly in the case of propeller shaft which is rotating while the vehicle is moving It is not possible to connect the fittings on the lubrication pints. In that case quick connector type coupling is used whenever vehicle becomes stationary/ these couplings are connected to the propeller pints for lubrication of these points This is/ of course/ done at the service station. Once the lubrication of propeller shaft is over connector coupling with hoses to be removed and attached on the chassis with the help of suitable clamps. For on board pump lubrication system/ propeller shaft joints are not possible to be lubricated They are lubricated manually as and when required.